Learning Objectives

- Differentiate sterilization and disinfection.

- Compare major sterilization methods.

- Apply Spaulding's classification framework.

- Analyze quality assurance processes.

- Evaluate reprocessing cycle failures.

Prerequisite Knowledge

- Basic microbiology and pathogens.

- Principles of infection transmission.

- Understanding of medical equipment.

Section 1: Sterilization Methods

Introduction to Sterilization

Sterilization is a critical process in infection prevention, defined as the destruction of all microbial life, including highly resistant bacterial spores. This is an absolute state; an item is either sterile or it is not. This process is mandatory for all critical medical devices—those that enter sterile tissue or the vascular system. The choice of sterilization method is dictated by the composition of the device, its heat and moisture sensitivity, and its packaging. In a modern Sterile Processing Department (SPD), several advanced technologies are employed to achieve sterility, each with its own specific mechanism, parameters, and limitations. Understanding these methods is fundamental for both clinical staff who use the equipment and administrative staff who oversee resource allocation and safety protocols.

1. Thermal Sterilization: The Power of Heat

Heat is the oldest, most reliable, and most cost-effective method of sterilization. It works by denaturing and coagulating essential proteins and enzymes within microorganisms, leading to irreversible cell death. There are two primary forms of thermal sterilization: moist heat and dry heat.

A. Moist Heat (Steam) Sterilization

Steam sterilization, commonly performed in a device called an autoclave, is the gold standard for sterilizing heat- and moisture-stable items. Its efficacy relies on the transfer of thermal energy from condensing steam to the items being processed. Saturated steam under pressure is a far more effective sterilant than hot air at the same temperature because it has a higher heat transfer coefficient and can penetrate materials more rapidly. The key parameters are time, temperature, and pressure. The presence of water also facilitates the destruction of microbial proteins (Rutala & Weber, 2019).

There are two main types of steam sterilizers:

- Gravity-Displacement Autoclaves: In this design, steam is introduced into the top of the chamber, and because steam is lighter than air, it displaces the heavier, cooler air, forcing it out through a drain at the bottom. This process is relatively slow and less efficient at penetrating complex instruments or porous loads. A typical cycle for wrapped instruments is 121°C (250°F) at 15 psi for 30 minutes, not including heating and cooling times.

- Dynamic Air Removal (Pre-vacuum) Autoclaves: These are more advanced and efficient. A vacuum pump actively removes air from the chamber before steam is injected. This ensures rapid and uniform steam penetration, even into complex lumens and dense packs. Because air removal is so effective, cycle times are much shorter. A common cycle is 132-134°C (270-273°F) at 28-30 psi for just 4 minutes. This efficiency makes them the primary workhorse in busy SPDs.

Advantages: Nontoxic, inexpensive, rapid cycles, highly effective, penetrates fabrics and lumens.

Disadvantages: Unsuitable for heat-sensitive or moisture-sensitive materials (e.g., plastics, electronics, powders). Can cause corrosion of carbon steel instruments.

B. Dry Heat Sterilization

Dry heat sterilization uses hot air and is suitable for materials that cannot tolerate moisture, such as powders, oils, and some glassware. However, it requires much higher temperatures and longer exposure times than steam sterilization because hot air is a less efficient conductor of heat. The mechanism of action is primarily oxidation of cellular components. There are two main types: static-air (relying on gravity convection) and forced-air (using a fan for circulation, which is more efficient).

Typical cycle parameters are 170°C (340°F) for 60 minutes or 160°C (320°F) for 120 minutes. These times do not include the significant period required for the load to reach the target temperature. Because of the high heat and long cycles, its application in modern hospitals is limited but remains essential for specific items (CDC, 2019).

Advantages: Nontoxic, does not corrode metals, can sterilize anhydrous materials.

Disadvantages: Long cycle times, high temperatures damage many materials (plastics, rubber), less efficient heat transfer.

2. Chemical Sterilization: Low-Temperature Solutions

For the vast majority of modern medical devices, particularly complex surgical instruments with integrated electronics, cameras, and delicate polymers, high-temperature sterilization is not an option. Low-temperature chemical sterilization methods are therefore essential.

A. Ethylene Oxide (EtO)

Ethylene oxide is a colorless, flammable, and highly toxic gas that is a potent sterilant at low temperatures (typically 37–63°C). Its mechanism of action is alkylation, a chemical reaction that disrupts the DNA and proteins of microorganisms, preventing them from metabolizing or reproducing. EtO is highly effective and has excellent penetration capabilities, making it ideal for sterilizing complex devices with long lumens, as well as pre-packaged kits containing a mix of materials.

The sterilization process is complex, involving four key parameters: gas concentration, temperature, relative humidity (40-80% is optimal), and exposure time (typically 1-6 hours). Following the sterilization cycle, a lengthy aeration period (8-12 hours or more) is mandatory to remove residual EtO gas, which is a known carcinogen and toxicant. This long total cycle time is the primary drawback of EtO sterilization.

Advantages: Excellent compatibility with a wide range of materials (plastics, electronics, elastomers), superior penetration.

Disadvantages: Very long cycle/aeration times, potential toxicity to staff and patients, flammable/explosive, requires dedicated ventilation and safety monitoring.

B. Hydrogen Peroxide (H2O2) Gas Plasma

This technology has become a leading low-temperature alternative to EtO. It involves creating a deep vacuum in the chamber, injecting a specific quantity of concentrated hydrogen peroxide (58-95%), and vaporizing it. A radio frequency or microwave energy field is then applied, creating a plasma state. This plasma contains free radicals (like hydroxyl and hydroperoxyl) that are highly reactive and lethal to microorganisms. They disrupt cell membranes, enzymes, and nucleic acids. The byproducts are non-toxic (water and oxygen), and the process is much faster than EtO.

Cycle times are typically 28-75 minutes, with no aeration required. However, H2O2 plasma has limitations. It cannot effectively sterilize items with long, narrow lumens, liquids, powders, or materials made of cellulose (paper, linen) because they absorb the peroxide and inhibit the process (AORN, 2022).

Advantages: Fast cycle times, non-toxic byproducts, safe for staff and environment, compatible with many heat-sensitive materials.

Disadvantages: Poor penetration for long/narrow lumens, material incompatibilities (cellulose, nylon, liquids), smaller chamber size, more expensive equipment.

C. Vaporized Hydrogen Peroxide (VHP)

VHP is similar to H2O2 gas plasma but does not use the plasma phase. Instead, it relies on circulating vaporized hydrogen peroxide at a controlled temperature and humidity to sterilize devices. It has better penetration capabilities for some lumens than plasma systems. The process also concludes with non-toxic byproducts. VHP sterilizers are gaining popularity for their efficacy and safety profile.

3. Radiation Sterilization

Radiation sterilization is primarily used by industrial manufacturers for single-use medical devices (e.g., syringes, sutures, catheters, implants). It is rarely performed in-house at hospitals. The mechanism is the ionization of key cellular components, particularly nucleic acids, leading to cell death. The two main types are Gamma irradiation (using Cobalt-60) and Electron-beam (E-beam) irradiation.

This method offers exceptional penetration and can sterilize products in their final shipping containers. However, the capital cost of the facility and the safety requirements for handling radioactive sources are immense, making it impractical for hospital settings.

Practical Application Examples

- Scenario 1: A standard stainless-steel surgical tray. The ideal method is steam sterilization (pre-vacuum autoclave). It is heat-stable, and this method is fast, effective, and economical.

- Scenario 2: A flexible fiber-optic endoscope. This device contains delicate optics, electronics, and polymers that would be destroyed by heat. The best choice is a low-temperature chemical method, such as hydrogen peroxide gas plasma or EtO, depending on the manufacturer's instructions for use (IFU).

- Scenario 3: A heat-sensitive powered drill with a long, narrow cannula. While H2O2 plasma is a low-temp option, it may not penetrate the long cannula effectively. Ethylene oxide (EtO) would be a more appropriate choice due to its superior penetration capabilities, provided the materials are compatible.

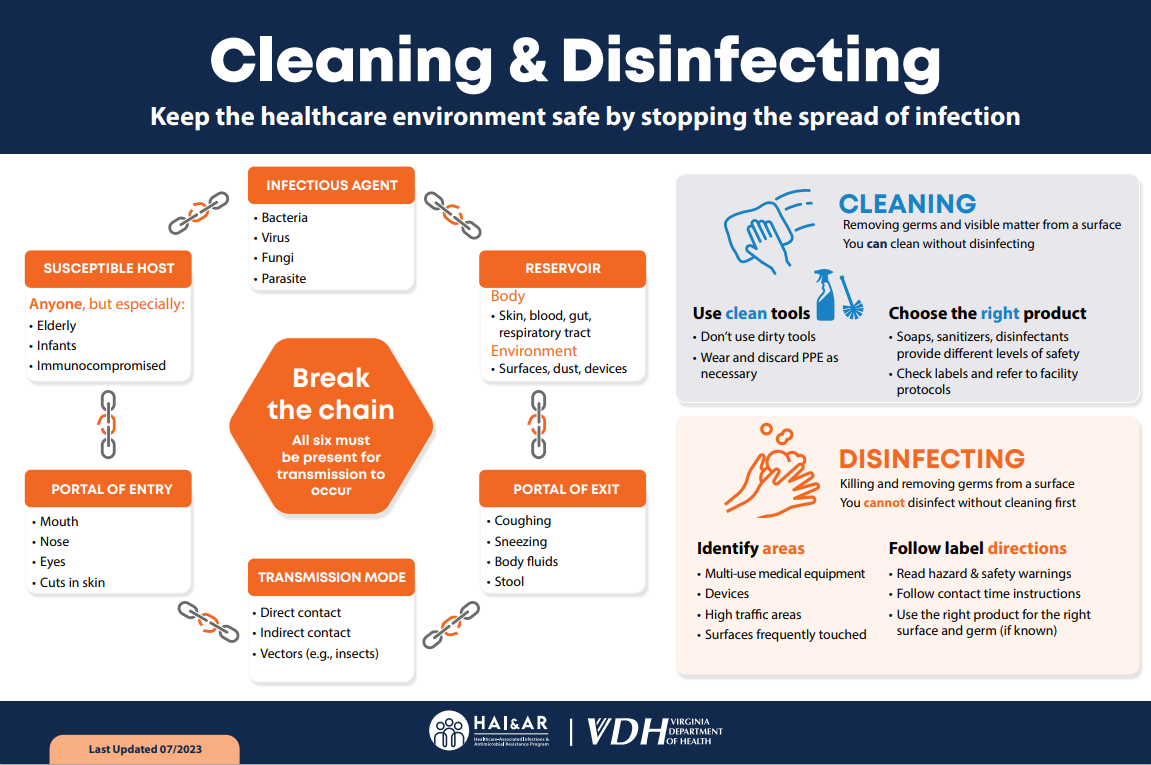

Sterilization Poster

Did You Know?

The autoclave was invented in 1879 by Charles Chamberland, a French microbiologist who worked with Louis Pasteur. His invention was a direct response to the need for a reliable method to sterilize laboratory equipment to support Pasteur's groundbreaking work on germ theory. The fundamental principle of using pressurized steam remains the cornerstone of sterilization over 140 years later.

Section 1 Summary

- Sterilization is the complete elimination of all microbial life, including spores.

- Moist Heat (Steam) is the preferred method for heat-stable items due to its speed, efficacy, and low cost.

- Dry Heat is used for moisture-sensitive items like powders but requires higher temperatures and longer times.

- Low-Temperature Chemical Methods (EtO, H2O2 Plasma) are essential for delicate, heat-sensitive instruments like endoscopes and cameras.

- Each method has a unique mechanism of action and a specific set of advantages, disadvantages, and material compatibilities that must be strictly followed.

Reflective Questions

- A new robotic surgical system is being purchased by the hospital. As an administrator or senior nurse, what key questions would you ask the manufacturer regarding the sterilization requirements for its complex, reusable components?

- Considering the long aeration times and potential toxicity of EtO, why do you think it is still widely used in hospitals despite the availability of faster technologies like H2O2 plasma?

Section 2: Disinfection Techniques

The Spectrum of Microbial Killing: Defining Disinfection

While sterilization aims for the absolute destruction of all microorganisms, disinfection describes a process that eliminates many or all pathogenic microorganisms, except bacterial spores, on inanimate objects. This distinction is crucial. Disinfection is not a single process but a spectrum of activity, ranging from highly potent to less rigorous methods. The appropriate level of disinfection is determined by the risk of infection associated with the use of the item being processed. This risk-based approach was brilliantly conceptualized by Dr. Earle H. Spaulding in the 1950s, and his framework remains the international standard for disinfection and sterilization protocols (Spaulding, 1968).

The Spaulding Classification: A Framework for Decision-Making

The Spaulding Classification categorizes medical devices into three classes based on the risk of infection involved in their use. This classification dictates the minimum required level of processing for each device.

1. Critical Items

These are items that enter sterile tissue, the vascular system, or any space through which blood flows. Any microbial contamination, even with low numbers of organisms, could lead to infection. Therefore, these items pose the highest risk and must be sterilized. Examples include surgical instruments, scalpels, cardiac catheters, and implants.

2. Semi-Critical Items

These items come into contact with mucous membranes or non-intact skin but do not penetrate sterile tissue. Mucous membranes are generally resistant to common bacterial spores but susceptible to other organisms like viruses and tubercle bacilli. These items require, at a minimum, high-level disinfection (HLD). Sterilization is preferred whenever possible, but HLD is an acceptable alternative for many devices. Examples include flexible endoscopes, respiratory therapy equipment, and anesthesia equipment.

3. Non-Critical Items

These items contact intact skin but not mucous membranes. Intact skin acts as an effective barrier to most microorganisms. Therefore, the risk of transmission is relatively low. These items require low-level disinfection (LLD). Some may only require cleaning. Examples include stethoscopes, blood pressure cuffs, bed rails, patient furniture, and floors.

Levels of Disinfection and Associated Chemical Agents

Based on Spaulding's framework, disinfectants are also categorized by their microbial killing power. The efficacy of any disinfectant is dependent on numerous factors, including: concentration, contact time, temperature, pH, and the presence of organic material (bioburden), which can inactivate many disinfectants.

A. High-Level Disinfection (HLD)

HLD is a process that destroys all vegetative microorganisms, mycobacteria, fungi, and viruses, but not necessarily high numbers of bacterial spores. For many semi-critical items, HLD is the standard of care. The process requires meticulous pre-cleaning followed by immersion in a chemical high-level disinfectant for a specific contact time and temperature, followed by thorough rinsing with sterile or filtered water and careful drying.

Common HLD agents include:

- Glutaraldehyde (≥2%): A long-standing HLD, it is effective but has several drawbacks. It is a potent respiratory and skin irritant, requiring use in well-ventilated areas with personal protective equipment (PPE). It also requires a long immersion time (e.g., 20-45 minutes depending on temperature and formulation) and has a limited reuse life.

- Ortho-phthalaldehyde (OPA): OPA (0.55%) is an effective HLD with several advantages over glutaraldehyde. It has superior mycobactericidal activity, a shorter immersion time (e.g., 12 minutes in the US), is less irritating, and does not require activation. However, it can stain skin and materials gray and is more expensive.

- Hydrogen Peroxide (≥7.5%): Accelerated hydrogen peroxide formulations are effective, fast-acting, and have a better safety profile than aldehydes. Their byproducts are oxygen and water.

- Peracetic Acid: Often combined with hydrogen peroxide, peracetic acid is a rapid-acting HLD that remains effective in the presence of organic matter. It is corrosive to some metals. Automated endoscope reprocessors (AERs) frequently use peracetic acid-based formulas.

B. Intermediate-Level Disinfection (ILD)

ILD destroys vegetative bacteria, most fungi, mycobacteria (the organism that causes tuberculosis), and most viruses. It does not kill bacterial spores. This level is typically used for some semi-critical items where HLD is not feasible and for non-critical surfaces that have been visibly contaminated with blood or body fluids.

Common ILD agents include:

- Alcohols (70-90% Ethyl or Isopropyl): Alcohols are excellent, rapid-acting disinfectants for surfaces. They are effective against a wide range of pathogens but evaporate quickly, making it difficult to maintain the required contact time. They are not effective for cleaning and can damage certain materials like rubber and plastics.

- Chlorine Compounds (Hypochlorites/Bleach): A 1:100 dilution of household bleach is a broad-spectrum, inexpensive ILD. A 1:10 dilution is recommended for large blood spills. Chlorine is highly effective but is corrosive to metals, inactivated by organic matter, and can be irritating to staff. It is the agent of choice for surfaces contaminated with pathogens like *Clostridioides difficile* spores, though this application technically pushes it toward a sporicidal agent with sufficient contact time (CDC, 2019).

- Iodophors: These are iodine-based compounds that are effective but can stain surfaces and fabric.

C. Low-Level Disinfection (LLD)

LLD destroys most vegetative bacteria, some fungi, and some viruses. It does not kill mycobacteria or spores. It is used for routine cleaning and disinfection of non-critical surfaces and patient care items that contact intact skin.

Common LLD agents include:

- Quaternary Ammonium Compounds (Quats): These are the most common active ingredients in hospital-grade disinfectant wipes and solutions. They are effective, non-corrosive, and have good cleaning properties. However, their effectiveness can be neutralized by some materials (e.g., cotton cloths) and hard water. Newer generation Quats have a broader microbial spectrum.

Practical Application Examples

- Scenario 1: A flexible colonoscope after a procedure. This is a semi-critical item as it contacts mucous membranes. It requires meticulous manual cleaning followed by high-level disinfection (HLD), typically in an Automated Endoscope Reprocessor (AER) using a chemical like OPA or peracetic acid.

- Scenario 2: A stethoscope used on a patient in an isolation room. This is a non-critical item. It should be cleaned and disinfected with an intermediate-level disinfectant (like an alcohol wipe) because of the higher risk of contamination in an isolation setting. For routine use, a low-level disinfectant is often sufficient.

- Scenario 3: A countertop in the nursing station where a blood specimen was spilled. This is a non-critical surface, but the visible blood contamination requires more than routine cleaning. The spill should be cleaned up, and the area disinfected with an intermediate-level disinfectant, such as a 1:10 dilution of bleach, to ensure all bloodborne pathogens are inactivated.

Did You Know?

Joseph Lister, a British surgeon in the 1860s, is considered the father of antiseptic surgery. Based on Louis Pasteur's work, Lister theorized that "invisible germs" were causing rampant post-surgical infections. He began experimenting with carbolic acid (phenol), spraying it in the operating room, on instruments, and on surgical wounds. His methods dramatically reduced surgical mortality rates and laid the foundation for modern aseptic and disinfection techniques.

Section 2 Summary

- Disinfection eliminates most pathogens but not necessarily bacterial spores.

- Spaulding's Classification is the guiding framework: Critical (sterilization), Semi-critical (high-level disinfection), and Non-critical (low-level disinfection).

- High-Level Disinfection (HLD) agents (e.g., OPA, Glutaraldehyde) are used for items contacting mucous membranes, like endoscopes.

- Intermediate-Level Disinfection (ILD) agents (e.g., Alcohol, Bleach) are used for non-critical items contaminated with body fluids.

- Low-Level Disinfection (LLD) agents (e.g., Quats) are used for routine environmental surface cleaning.

- Effective disinfection depends on proper cleaning, concentration, and contact time.

Reflective Questions

- Your hospital is seeing a rise in healthcare-associated infections caused by *C. difficile*. How would this information change your protocols for daily room cleaning and disinfection for all patients, not just those with a known infection?

- A new reusable, non-critical patient monitoring device is introduced. The manufacturer's instructions for use (IFU) state it can be cleaned with a specific proprietary wipe. What steps should the infection control committee and materials management take before approving its use hospital-wide?

Section 3: Quality Assurance in Sterile Processing

The Imperative of a "Culture of Quality"

The processes of sterilization and high-level disinfection are complex and involve numerous critical steps. A single failure at any point in the chain—from initial cleaning to final storage—can result in the use of a contaminated device on a patient, with potentially devastating consequences. Therefore, a robust Quality Assurance (QA) program is not an optional add-on; it is the fundamental backbone of any Sterile Processing Department (SPD). A comprehensive QA program ensures that sterilization processes are consistently effective, reliable, and reproducible. It involves a multi-faceted approach, encompassing process monitoring, equipment maintenance, documentation, staff training, and competency validation (Seavey, 2016).

The goal of QA is to move from a reactive state (finding failures after they occur) to a proactive state (preventing failures before they happen). This requires a "culture of quality" where every team member feels empowered and responsible for patient safety.

The Three Pillars of Sterilization Process Monitoring

Routine monitoring of sterilization cycles is essential to verify that the equipment is functioning correctly and that the parameters for sterility have been met. This monitoring is accomplished through a combination of three distinct but complementary methods: physical, chemical, and biological.

1. Physical Monitoring

Physical monitoring involves the direct observation and recording of the physical parameters of the sterilization cycle. This is the first line of verification. For every single cycle run, the operator must check and document the following:

- Cycle Printouts/Digital Records: Modern sterilizers provide detailed printouts or digital records of the cycle. This data includes the time, temperature, and pressure at each stage of the cycle (e.g., conditioning, sterilizing, exhausting). The operator must verify that the printout matches the selected cycle parameters and that those parameters were met for the required duration.

- Gauges and Displays: The operator must visually confirm that the gauges and displays on the sterilizer itself correspond with the data on the printout. Any discrepancy could indicate a malfunctioning sensor or recording device.

At the end of the cycle, the operator reviews this physical data to determine if the cycle was successful. A load should not be released if the physical monitors indicate that any parameter was not met. This is a critical checkpoint before any other indicators are even examined.

2. Chemical Monitoring

Chemical Indicators (CIs) are devices that use one or more chemical reagents to visually confirm that the physical conditions for sterilization have been met in a specific location. They provide information at the point of use and come in various classes. It is crucial to understand that CIs do not prove that an item is sterile; they only prove that it has been exposed to the conditions necessary for sterilization (AAMI, 2017).

- External Indicators (Class 1 - Process Indicators): These are applied to the outside of every package (e.g., indicator tape, labels). They are designed to show that the package has been *exposed* to the sterilization process. Their main purpose is to differentiate processed from unprocessed items. A color change on the external tape does not, by itself, indicate that the contents are sterile.

- Internal Indicators (Classes 3, 4, 5, & 6): An internal CI is placed inside every package in the most challenging location for the sterilant to reach. This verifies that the sterilant penetrated the packaging and reached the instruments inside.

- Class 4 - Multi-parameter Indicators: React to two or more critical parameters (e.g., time and temperature for steam).

- Class 5 - Integrating Indicators: Designed to react to all critical parameters of a specific sterilization cycle. Their performance is engineered to be equivalent to or exceed the performance of a biological indicator, giving a high level of assurance.

- Class 6 - Emulating Indicators (Cycle Verification): Designed to react to all critical parameters of a *specific* sterilization cycle (e.g., 134°C for 4 minutes). They are very precise and used for cycle verification.

- Bowie-Dick Test (Class 2 - Specific Use): This is a special CI used only in pre-vacuum steam sterilizers. It is run daily in an empty chamber to test the efficacy of the air removal system. A failure (uneven color change) indicates an air leak or inadequate vacuum, which would compromise steam penetration.

3. Biological Monitoring

Biological Indicators (BIs) are the "gold standard" for sterility assurance. They are the only process indicators that directly monitor the lethality of the sterilization process. BIs contain a known population of highly resistant bacterial spores. If the sterilizer is effective, it will kill these hardy spores. If the spores survive, the cycle is considered a failure.

- Spore Type: The species of spore used is specific to the sterilization method. For steam sterilization, Geobacillus stearothermophilus is used. For Ethylene Oxide (EtO) and dry heat, Bacillus atrophaeus is used.

- Testing Frequency: The Association for the Advancement of Medical Instrumentation (AAMI) and the Association of periOperative Registered Nurses (AORN) recommend that sterilizers be monitored at least weekly, but preferably daily, with a BI. Furthermore, every load containing implantable devices must be monitored with a BI. The load should be quarantined until the result of the BI is known (AORN, 2022).

- Process: A processed BI and an unprocessed control BI from the same lot are incubated. Modern systems use a rapid-readout technology that can provide results in as little as 24 minutes to a few hours, based on detecting enzyme activity from surviving spores. A positive result (spore growth) requires immediate action.

Documentation and Recall Procedures

Meticulous documentation is the cornerstone of a defensible sterile processing QA program. Records must be maintained for every cycle, linking the sterilizer, cycle number, date, and contents of the load to the results of the physical, chemical, and biological monitors. This traceability is essential. In the event of a monitoring failure (e.g., a positive BI), this documentation allows the SPD to execute a precise recall. A recall procedure involves identifying every item from the failed load, retrieving them from all locations (including operating rooms and clinical units), and reprocessing them. A thorough investigation into the cause of the failure must be conducted and documented before the sterilizer is returned to service.

Practical Application Examples

- Scenario 1: A Bowie-Dick test fails. At the start of the day, the SPD technician runs the test in the pre-vacuum steam sterilizer, and the indicator sheet shows a large air pocket (uneven color change). Action: The sterilizer is immediately taken out of service. Maintenance is called to investigate for potential air leaks in the gasket or plumbing. The sterilizer cannot be used until the problem is fixed and a successful Bowie-Dick test is run.

- Scenario 2: A positive Biological Indicator. The rapid-readout incubator alerts to a positive BI from a steam load run the previous day. Action: The SPD supervisor initiates a recall. Using the load documentation, all packs from that specific load are identified and retrieved. The sterilizer is taken out of service. An investigation begins, examining the physical and chemical monitors for that load and recent loads, reviewing operator practices, and checking maintenance records. The sterilizer is re-challenged with three consecutive BI tests in empty cycles. Only after three consecutive negative BIs can it be returned to service.

Did You Know?

The concept of using biological indicators dates back to the early 20th century. Scientists needed a way to be certain that heat treatments were effective against the most resistant forms of life. They identified thermophilic (heat-loving) spore-forming bacteria as the ultimate challenge. The logic was simple and powerful: if a process can kill the toughest known organism, it can be trusted to kill everything else. This principle remains the highest level of sterility assurance today.

Section 3 Summary

- A robust Quality Assurance program is essential for patient safety in sterile processing.

- Physical Monitoring involves checking cycle printouts and gauges for every load to verify time, temperature, and pressure were met.

- Chemical Indicators (CIs) are used externally and internally to verify sterilant exposure and penetration. They do not prove sterility.

- Biological Indicators (BIs), containing resistant spores, are the gold standard and directly challenge the lethality of the sterilization process.

- Comprehensive documentation is critical for routine process control and for executing effective recalls in the event of a failure.

Reflective Questions

- A hospital administrator is proposing to cut the budget for the SPD, suggesting reducing the frequency of biological indicator testing from daily to weekly to save money. How would you argue against this proposal, using principles of quality assurance and risk management?

- An operating room nurse opens a surgical tray and notices the internal chemical indicator has not fully changed color. The surgeon is waiting and the patient is on the table. What are the immediate actions the nurse must take, and what are the downstream implications for the SPD?